|

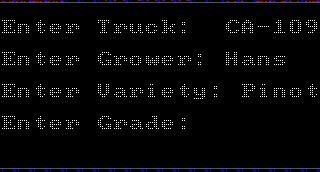

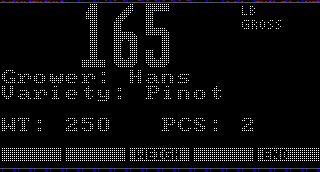

Lift Truck Scale Support

Lift Truck Scale Support

- Greatly reduced weigh time

- Weighing on the move increases productivity

- Radio Communication or wired batch download

- Optional on-board label / ticket printer

|

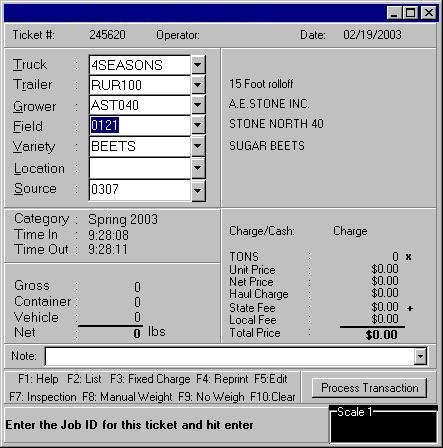

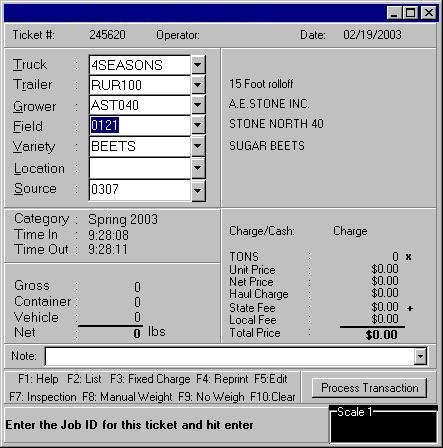

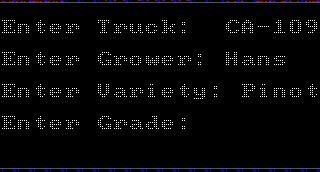

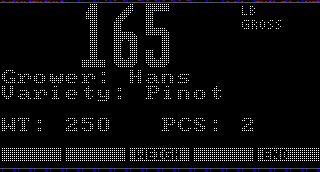

Truck / Deck Scale Support

- Fast Tickets

- Drop-down lists for growers, vehicles, varieties, etc.

- Stored tares for one-weigh ticketing

- Multiple scale support speeds throughput

|

Comprehensive Reporting

- Payment processing

- Browser based on-line accessible grower daily reports

- Ad-hoc queries for "what if" analysis / user defined reports

- Data export to accounting packages, MS Office, email, web, ODBC, mainframes

|

|

Ease of Use

- Quick learning curve for new operators

- Barcode / Magstripe / RFID reduces keystrokes

- Automatic security and audit facilities

- User specified field names to match terminology

|

Flexibility

- Networking for multi-user over LAN / WAN / Wireless

- Unattended operation cuts labor costs

- Job tracking and accumulation

- Quality sampling for lab testing

|

Tracks and reports on:

From whom: Growers / Crew / Haulers / Driver

From where: Plot / Vineyard / Field / House

On what: Truck / Trailer / Cart

In what: Pallets / Totes / Flats

What kind: Variety / Type / Grade

How much: Lift Truck Scale / Truck Scale / Deck Scale

When: Time / Date

Where to: Storage / Processing location

How good: Quality samples for lab test

|

|

|

Partial Client List

|

|

Villines Foods

Spreckles Sugar

Holly Sugar

American Crystal Sugar

Western Sugar

Sydney Sugar

Wyoming Sugar

Pacific Northwest Sugar

Rainsweets, Inc.

Vita Fresh Fruit Juice

|

Top of Page

Seed Blending System

Six (6) individual hoppers, equipped with a variable speed vibratory feeder,

are mounted on load cells. The operator

enters a blend/formula number into the weight indicator/controller, which

controls output proportionately. Each feeder dispenses onto a

takeaway conveyor which eventually feeds into a "finished mix" hopper

with bagger.

Operation

Controller Setup:

1) Supervisor will need to enter the various blend numbers and their

percentage per hopper requirements

2) There could be formulas where we will not need to use all 6 hoppers,

as in the case of simple blends that are only a three or four variety mix

Operator Sequence:

1) Once all the supply hoppers have been filled, a blend number is keypad

entered into the 1310

2) Upon verification of correct blend number the 1310 prompts for "PRESS START BUTTON"

3) Operator depresses start button, 1310 energizes the appropriate Eriez feeders

with an output level signal and begins to monitor weight loss/time long enough

to establish the appropriate output level to send for each hopper so as to get

the correct blend

4) There is an automatic/manual switch on the control panel for times

when they will need to empty individual supply hopper and/or other requirements

Top of Page

|